Project Overview

For my introduction to engineering course, my team was challenged to design, build, and program a fully autonomous robot capable of navigating difficult terrain, detecting fires, determining topography, and extinguishing specific candles—all without human intervention after the start signal.

As mechanical lead and primary programmer, I designed the robot's unique folding platform extinguishing system, integrated all sensors, and implemented the state-machine control logic in Arduino C++. The result was a robot that successfully completed all mission objectives in under 2 minutes.

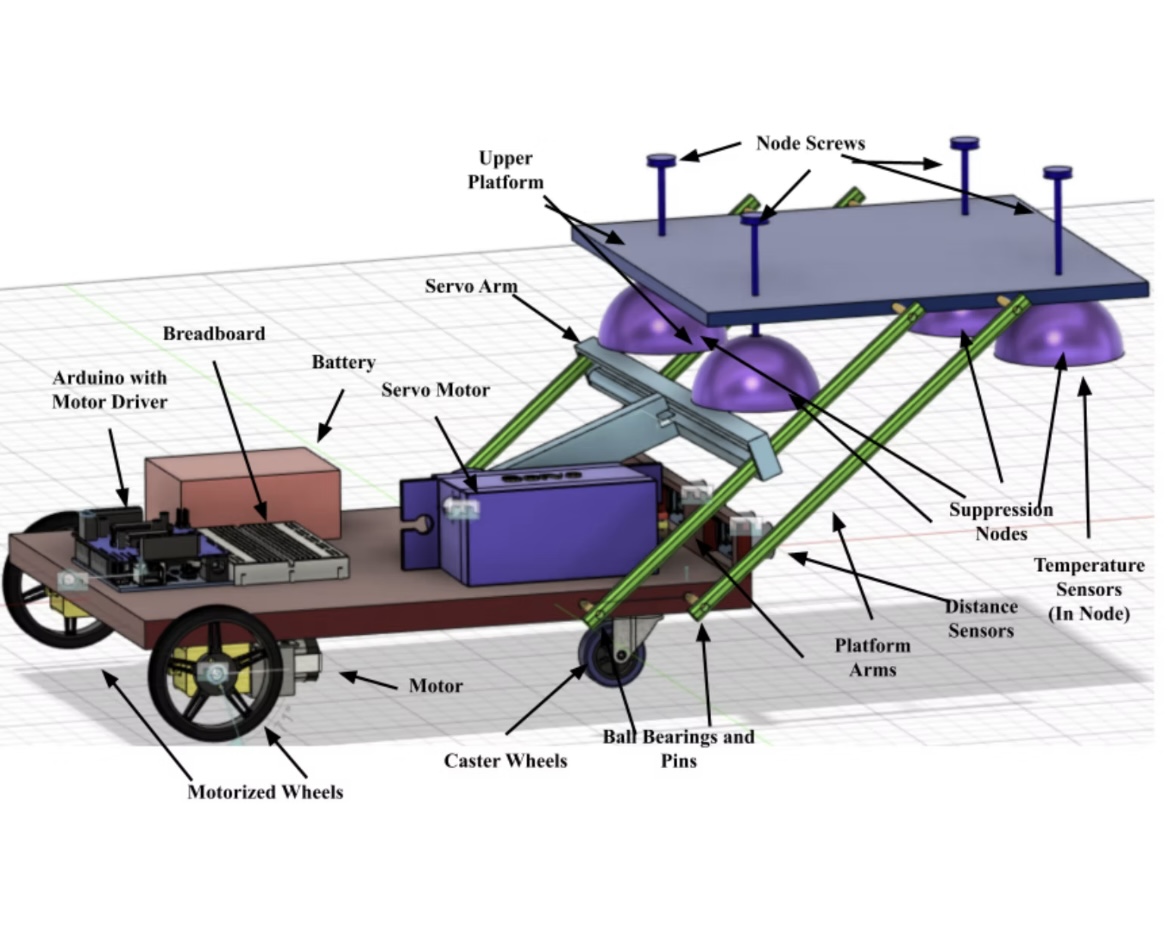

Final autonomous fire truck with extended suppression platform

Final autonomous fire truck with extended suppression platform